The PHC piles can be installed into the ground by hammer driving, pre-augering and centre-augering.While using hammer driving. the PHC piles will stand hard drinving and be driven through hard soil layer to rigid bearing stratum. Thus ,high bearing capacity can be obtained. This method also has the advantage of easy control and low cost. In general,piling can be done by percussion method.In case of encountering some obstructions such as lage boulders or the environmental limitation to the driving noise and vibration,other installed methods are recommended.

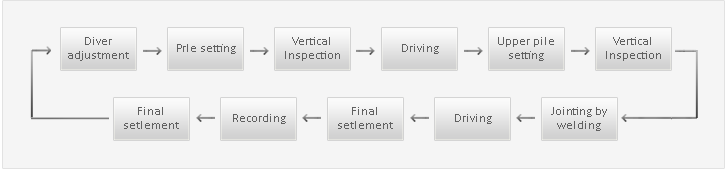

Diesel hammer driving procedure:

Relation between diesel hammer weight and pile length:

| Dim (mm) |

Thickness (mm) |

Ram Weight (t) |

|||||

|---|---|---|---|---|---|---|---|

| 2.5 | 3.5 | 4.5 | 60. | 7.0 | 8.0 | ||

| 300 | 70 | 21m | 30m | 38m | 51m | --- | --- |

| 400 | 95 | 21m | 30m | 38m | 51m | --- | --- |

| 500 | 100 | --- | 20m | 27m | 35m | 42m | 48m |

| 125 | --- | --- | 23m | 31m | 37m | 41m | |

| 600 | 110 | --- | --- | 21m | 28m | 33m | 37m |

| 130 | --- | --- | 18m | 24m | 28m | 32m | |

Note: In cases where the soft ground, the values listed in this table may be higher than the maximum pile length.

Caution:

- 1.The driving direction of hammer,shaft centres of helmet and pile should be kept on the same aligment at all time of driving.

- 2.A more than 20mm thcikness cushion made of hard timber or other proper materials should be places uniformly between pile head and helmet,and replaced regularly.

- 3.A 150-200mm thickness cushion made of hard wood with vertical grain should be laid between hammer and helmet.The inside diameter of the helmet should have a proper clearance over the outside diameter of the pile head. Suck clearance is recommended to be 20-30mm.

- 4.Minimum pile space should be Л•D (D is the outside diameter of pile).

- 5.While jointing piles by welding.the elecrode diameter should not be less than 4mm.The throat between two piles to be jointed should be fully filled with melting metal.After finishing welding.the futher driving of piles can not be carried out soon until the welded part is cooled down naturally. The cooling time of at least 8mins is recommended.

- 6.Piles should be unloaded on a firmly level place of site.and stacked no more than two layers.

Final settle ment and calculation of bearing capacity:

- 1.Conditions of shopping blow should be determined by the way of trial piling of possible,or by calculation of Hilley formula and previous related piling experiences.

- 2.When the piles are drivern nearly to pre-determined depth,final settlement and temorary elastic compression should be measured. Ingeneral. the final settlement is recommended to be no less than 20mm for every ten blows.Even in case of very soft ground where the layer of bearing stratum is thin,the final settlement is recommanded to be no less than 15mm for every ten blows.

- 3.The bearing capacity can be determined by Hilley formula.

Where Ra:Allowable bearing capacity(kN) E:Energy of ram (kN·m) S:Final settlement(m)

C:Temporary elastic compression(m) ef:Hammer efficiency (ef=0.9) e:Coefficient of restiution(e=0.4)

W:Weight of ram(kN) P:Pile and helmet weight(kN)

Driving should be stopped graduadlly when the specified bearing capacity is obtained.Excessive driving is not only unnecessay,

but may be also harmful to the piles.